Photo by TheDigitalArtist via Pixabay

Attract the Right Job Or Clientele:

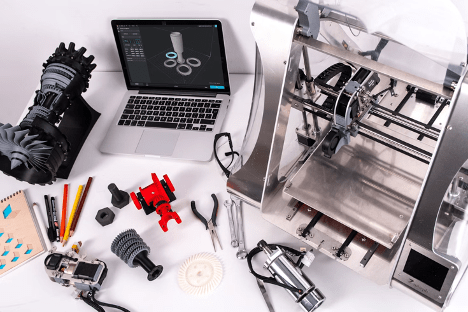

How to Ensure High-Quality 3D Prints for Your Business

The 3D printing business is a relatively new subsection getting more attention from different people. Suppose you’re running a 3D printing business and want to provide customers with the best possible product as much as possible. In that case, you like to ensure consistent product quality. Otherwise, you might stop getting a consistent flow of customers.

Accordingly, our guest blog offers insights on ensuring high-quality 3D prints for your business.

_______________________________________________________________________________________________

Ensure High-Quality 3D Prints

Photo by ZMorph All-in-One 3D Printers on Unsplash

Inspecting the Filament Before Printing

When you’re running a 3D printing business, you’re going to use your 3D printer constantly. Given the load of work you will give, you should be mindful of how you utilize it.

Before printing, make it a habit to check your filaments and where you load them. Like any other printer, you can sometimes encounter jams that cause your printing to stop. Most of the time, your 3D printer won’t print because of a knot in the filament’s container. You can see these knots easily to remove the jam before printing.

You can fix the jam by removing the filament from the compartment once the printer stops and then removing that knot. You should be able to start printing after you’ve removed that knot.

Ideally, it would help to use 3D filaments from the same brand as your 3D printer to be as compatible as possible. Although that’s not a hard and fast rule, it reduces any complications that may arise simply from poor compatibility.

Reduce the Layer height of Your 3D Prints

Mastering the best layer height for your 3D prints is essential in ensuring that your models come out at the best quality possible.

If you don’t know what layer height is, it’s how thick the 3D printer will print out the layers. Your layer height will depend on the nozzle size and your slicer’s settings.

When you have a higher layer height, your printer will finish faster, but you’ll be compromising print quality and strength. On the other hand, if you have a lower layer height for your 3D prints, it will take a while before your 3D printer will finish printing. However, the resulting models will be more robust and have a higher quality in detail.

The ideal layer height changes depending on your nozzle size and the material you’re using. Therefore, you should make sure to keep that in mind when you’re adjusting the optimal layer height for your projects.

Keep the Nozzle Temperature at the Optimal Level

Another aspect of 3D printing that affects the quality of your prints would be the nozzle’s temperature.

The temperature of your nozzle will affect how smoothly the filament will melt and flow from the nozzle. If your nozzle temperature is too high, it can cause an over-extrusion and even burn your filaments. On the other hand, if the temperature’s too low, you can get under-extrusion, making your filament flow much slower and not melting precisely.

To avoid this, follow the guidelines set by the filament manufacturer you’re using at the ideal temperature. It would help if you also looked at the recommended printing temperature for your specific 3D printer.

It’s best to test things out by slowly increasing the temperature from the lowest recommended temperature until you find a happy middle that creates the best quality print.

Use A High-Quality Slicer

A slicer is a software that instructs your 3D printer how to print out your model by slicing a 3D model into different layers. This information is what your 3D printer uses to know how to print. Without a high-quality slicer, your printer wouldn’t be able to start printing in the first place.

Luckily, there are quite a few options out there, many of which are free. However, make sure to discern whether their quality is excellent.

One factor to consider would be its compatibility with your 3D printer. If your slicer doesn’t support your 3D printer, consider looking for one with a custom printer profile option.

When looking for the best slicer for your printing business, you should look for the ability to change the layer height, print speed, cooling settings, support structures, and more advanced features.

Reduce the Printing Speed

We’ve mentioned earlier that lowering the layer height affects the quality of the output but also slows down the printing speed.

Lowering the printing speed prevents your printer from moving around too fast. When your printing speed is too fast, it ends up causing vibrations that can translate and be present in the final output. These usually manifest themselves as rings around the edges that affect the visual quality of your prints.

By slowing things down, your extruder doesn’t have to move from point to point at a certain speed, which could cause jerks and movements that affect the quality of the print.

Address All Gaps

If you start noticing that your final product keeps producing gaps and holes in the final output in places you don’t want them to be, then you should address those immediately.

There are different causes, but the best way to solve them is by identifying the specific causes. Usually, the causes of these holes and gaps can be the following:

- Clogged nozzle

- The filament retracted too much during non-extrusion

- Printing speed is too fast

- Slow filament feed rate

- Sudden temperature changes for the filament

- Under-extrusion

- Wet Filaments

Once you know the cause of the holes and gaps, you can solve the cause directly.

Lower the Flow Rate to Create Lighter Supports

If your supports are too strong, you might create imperfect print surfaces after removing them. That’s a waste of time, money, and effort.

To avoid that issue, consider lowering the flow rate to an adequate amount. That way, it would be easier for you to remove your supports since they’re lighter.

Just make sure you don’t overdo it. Otherwise, you can make it harder for layers to adhere to one another.

Ensure the Stability of Your 3D Printer

We briefly mentioned earlier that vibrations of our 3D printer as it prints will affect the quality of the print. A faster printing speed can cause the extruder to move from point to point too fast, causing vibrations. But another factor that can cause unwanted vibrations would be an unstable foundation for your 3D printer. Therefore, make sure that your 3D printer is on a sturdy surface. You should not have it on potentially wobbly surfaces, like a shaky table.

Replace Your Nozzle With A New One

You should check on your nozzles if you’ve been printing for a while. Sometimes, the wear and tear of a regularly used nozzle can cause it to wear down, get damaged, or clogged.

When you get a fresh nozzle, you can avoid poor print quality. Just make sure that it’s suitable and compatible to the size of your 3D printer. Be mindful of the nozzle’s material, which also affects how long it lasts.

Perform Post-processing On Your Prints

Your post-processing habits for your prints also matter regarding the quality of the result.

A sharp hobby knife can be helpful with removing the supports precisely. You can also use sandpaper to smoothen excess supports down, especially if you plan on polishing or painting over these spots.

It would be best if you tweaked your post-processing plans depending on what materials you’re using.

In Conclusion: Ensure High-Quality 3D Prints

These tips should help you determine how to optimize your print results for your 3D printing business. That way, you consistently provide your customers with 3D print results that are high-quality, strong, and long-lasting.

For more Insights, Visit Elinor’s Amazon Author Page

Communicate to Attract Interest

Be A Story-Teller

“Believe, Become, Empower”

Related Blog Stories:

Humanos Magazine

Available in English and Spanish: Click to Learn More and Subscribe

Click Here to Apply to Star in the Inspired Movie!

Sales Tips: Ensure High-Quality 3D Prints

1. Know the needs and desires of your audience, including your next new employer, in detail. Be Inspired and Inspiring!

2. Research the top equipment for 3D prints.

3. Research the top providers to compare and contrast the cost of doing it yourself.

4. Upon consulting with suppliers, ask specific questions to avoid overlooking essential matters.

5. Ask clientele about their preferences.

6. Realize repetitive requests upon questioning your clientele.

7. Prioritize everything you need in place to ensure high-quality 3D prints.

8. Check with staff for their recommendations.

9. Test the process and then ask for honest feedback.

10. Celebrate Success!

Today’s insights are provided to help you achieve the Smooth Sale!

RESOURCES FOR PERSONAL AND BUSINESS GROWTH:

Advisorpedia Publishes information to help advisors build their practice, and those interested in the markets choose investments and find inspiration.

BabyBoomer – A trusted media source that collects and curates all the news and resources, plus offers a wide variety of excellent courses for the Baby Boomer generation.

BizCatalyst360 Presents a life, culture, and biz new media digest as a hub of creative expression and personal growth.

CatCat: Build your future one skill at a time.

ContactOut is a web-based platform that enables users to search for contact information and uncover contact details, including email addresses, phone numbers, and other personal data.

Executives Diary Magazine Features leaders from varying fields sharing their inspiring stories, including Elinor Stutz.

Fedica Realize your followers’ interests to create tailored content to encourage a returning and referring clientele.

Greg Jenkins Consulting LLC – Helping organizations realize the value of diversity to build inclusive, evolving, high-performing cultures.

Growth Hackers – Helping businesses globally grow with lead generation, growth marketing, conversion rate optimization, data analytics, user acquisition, retention, and sales.

Humanology International Institute – The institution that develops and safeguards humanology as a discipline worldwide.

Inclusion Allies Coalition: “Everyone is welcome here.” Learn more to train teams and join the advocacy program.

Internet Advisor Find the internet service right for you among 2083 internet providers across 36,380 cities; plus, Cellphonedeal compiles excellent deals on phones, plans, and prepaid to furnish you with the best options in your area.

Inspired Movie Inspiration is a game changer for most; apply to an inspiring guiding light in conjunction with Producer/Director of the Inspired movie Patryk Wezowski,

Kred Connect with top-rated influencers to learn from and grow your networks.

LinktoEXPERT “It is not who you know – who knows you and what your expertise can do for them, plus understand the value of hiring you.”

Lotus Solution LLC Helps organizations create diversity and inclusion to ensure fairness and work through customized consulting, training, and keynote speeches.

Onalytica: Find relevant influencers for your brand.

SalesPop! Purveyors of Prosperity; How to Compete against Yourself to Excel in Your Career.

Simma Lieberman, “The Inclusionist,” helps develop inclusive leaders from the inside out to champion diversity and build equitable, inclusive cultures at every level.

Yoroflow offers a comprehensive suite of digital workplace platforms to help you streamline your day-to-day operations, manage your finances, and grow your business.

Vunela Provides a unique opportunity to view Videos and read articles by World Leaders.

Win Win Women is the world’s only interactive network and an international community for women. Women WIN when they receive solutions + Experts WIN when they provide solutions = Win Win Women.